Achieve Your Ideal Surface Treatment

Optimize Your Parts Performance with Bales

Thanks to rising demand from packaging and medical applications, the global plastic injection molding market is projected to grow by 4.8% from 2020 to 2027.* But it’s difficult for manufacturers to meet demand amid striking supply chain disruptions and unplanned downtime.

You can improve productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for plastic injection molding manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From slides to sleeves, your components for all applications will benefit from our legacy of customer satisfaction, integrity, and innovation.

Plastic Injection Molding Solutions FAQs

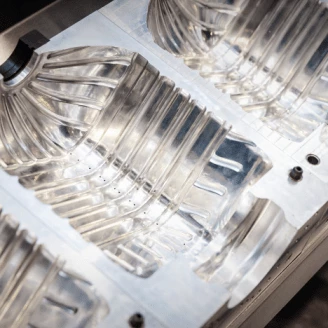

Efficiency and precision are essential in plastic injection molding. This FAQ section discusses our high-performance coatings, which reduce wear, enhance mold release and improve the quality of molded products. Let us show you the benefits of partnering with us for your plastic injection molding needs.

If you are ready to get started, please visit our Request a Quote page and get started today.

Our dedicated FAQ page has more details to help you make the right choice for your needs.

Solve All Your Metal Surfacing Issues

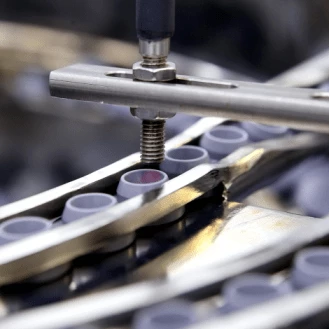

Plastic injection molding processors need to maximize productivity. Bales' quality coatings prevent oxidation, wear, and sticking for all plastic injection molding applications. Whatever your issue, we can solve it! Are you looking for more efficient finishing? Use Bales' highly skilled polishing department to minimize transit to multiple suppliers.

NIBORE™

There’s a lot to love about Bales’ proprietary NIBORE™ coating. A go-to solution for many manufacturers, it offers superior lubricity and release, excellent abrasion resistance, plus uniform plating.

- 0.05> Coefficient of Friction

- 54 Rockwell Hardness

- 0.00005 to 0.0005” Plating Thickness Range

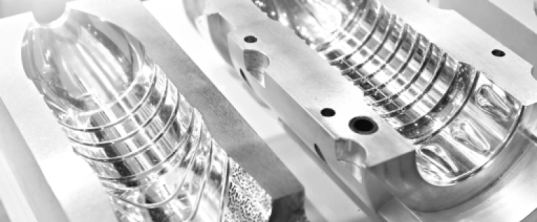

Mold Polishing

Accurate mold polishing creates a uniform surface finish that will optimize part performance. Partner with Bales for polishing that matches your precise specifications. We’ll help you select the best finish for common and complex manufacturing issues:

- PART STICKING - Create easier release from the mold.

Case Study: NIBORE™ Fixes Sticky Mold Lifters

Mold lifters are supposed to help, not hinder, a production run. Uniphase, Inc., a custom injection molding company, had started a high-volume program for one of its customers but the side-ejection lifters kept pushing the parts out on an angle, causing them to stick to one side of the mold or the other.

READ CASE STUDY