Achieve Your Ideal Surface Treatment

Maximize Your Parts Performance with Bales

Solid growth lies ahead for food processing and packaging companies, thanks to increased demand for convenience food and automated manufacturing. Analysts expect the markets to grow by an average of 5.1% through 2028.* But supply chain issues and workforce shortages are creating challenges for manufacturers.

You can improve productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for food processing & packaging manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From automation parts to cutting equipment, your food processing and packaging components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Food Processing & Packaging Solutions FAQs

Safety and quality are crucial in food processing and packaging. Our coatings meet these standards, as this FAQ section explains. Discover how our solutions ensure safety and efficiency in food processing applications with rigorous environments and heavy use.

Are you ready for a precise quote on your food processing project? Visit our Request a Quote page and get started today.

If you're still exploring options, find more details on our dedicated FAQ page.

Solve Your Corrosion and Release Issues

Bales’ Electroless Nickel, Hard Chrome, and proprietary NICKLON™ coatings are ideal for food processing or packaging applications. These coatings protect against corrosion while achieving optimal lubricity and release. Are you looking for more efficient finishing? Use Bales’ highly skilled polishing department to minimize transit to multiple suppliers.

Electroless Nickel

Bales’ exceptionally thin Electroless Nickel coating protects against corrosion and abrasion without altering the surface finish of your mold. It also prevents build-up and maintains tolerance.

- .003” > Plating Thickness

- 1.0 mil deposit, 1,000+ hours Corrosion Properties

- 45 Rockwell Hardness - HVN100

NICKLON™

Bales’ proprietary NICKLON™ coating combines Electroless Nickel with PTFE. It protects against wear and corrosion while providing superior lubricity and release.

- 45 Rockwell Hardness

- 0.10 Coefficient of Friction

- PTFE 8-9% Composition (WT)

Hard Chrome

Hard Chrome is a reliable and durable coating for the most abrasive applications. It prevents wear and corrosion while mimicking the finish of base materials.

- 72 Rockwell Hardness

- 1250°F Max Operating Temperature

- 6.9 g/cm3 Density

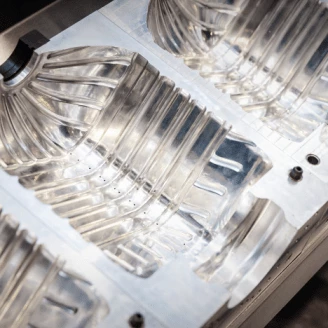

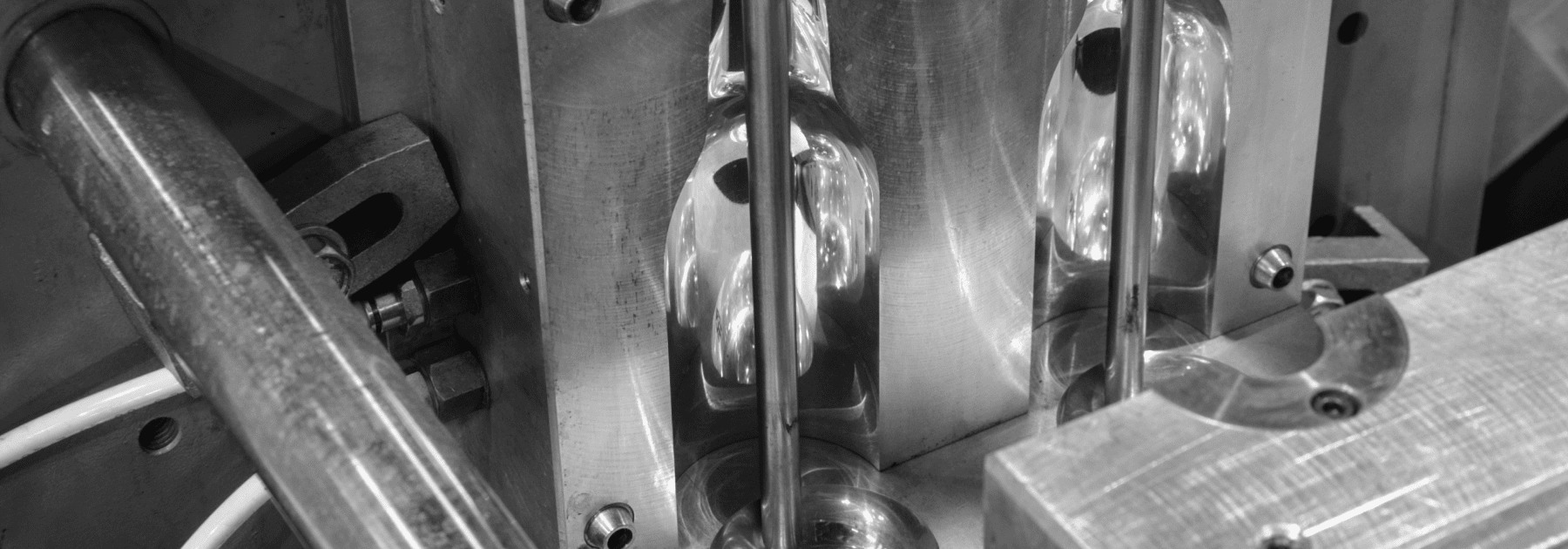

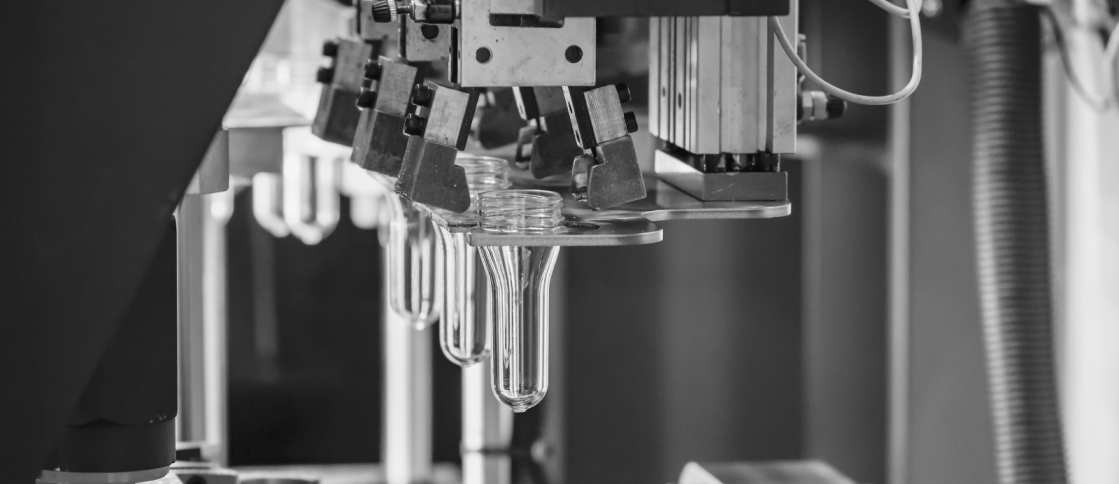

Case Study: Polishing Achieves Crystal-Clear Finish

A customer needed its highly visible parts—tumbler cups for the food and beverage industry—to have a very precise finish. Fortunately, polishing steel molds to assure the finest finishes on visible parts is a Bales specialty.

READ CASE STUDY