Achieve Your Ideal Surface Treatment

Advance Your Parts Performance with Bales

As more systems become automated, the global automation and linear motion market continues to grow. Analysts forecast 7.2% growth from 2021 to 2026.* But manufacturers are struggling to keep up amid unprecedented unplanned downtime and supply chain disruptions.

You can improve productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for automation and linear motion manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From face rails to rollers, your automation and linear motion components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Automation & Linear Motion Solutions FAQs

Precision and efficiency are vital in automation and linear motion applications. Our coatings ensure the optimal performance of components in these sectors. This FAQ section addresses common queries about how our advanced solutions reduce wear, enhance longevity, and improve performance in automation components, aligning with the dynamic needs of the industry.

Ready to advance your automation project with our expert solutions? Request a precise quote today.

For more resources to help you make the right decision, our dedicated FAQ page has more details.

- Corrosion Resistance: Metal finishing, such as plating or coating, creates a protective layer that shields the metal from environmental factors like moisture, chemicals, and oxidation, thereby preventing or reducing corrosion.

- Enhanced Durability: Finishing processes can increase a metal's resistance to wear, abrasion, and scratches, thereby extending the lifespan of components and ensuring they can withstand harsh conditions.

- Improved Aesthetics: Finishing techniques can enhance the appearance of metal surfaces, providing a polished, decorative, or customized look that aligns with design preferences.

- Smoothness and Lubrication: Finishing processes can create smoother surfaces, reducing friction and improving the performance of moving parts. Some finishes also provide built-in lubrication properties.

- Improved Aesthetics: Finishing techniques can enhance the appearance of metal surfaces, providing a polished, decorative, or customized look that aligns with design preferences.

- Coating Impact: Applied coatings, such as plating or surface treatments, can modify the hardness of the surface layer independently from the bulk material. Coatings can add hardness, wear resistance, and other properties.

Solve Your Abrasion and Release Issues

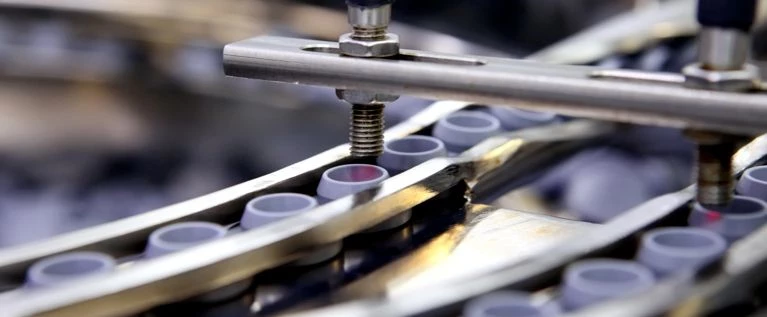

Automation and linear motion users need to maximize production. Avoid downtime caused by wear and sticking with Bales’ proprietary NIBORE™ and Diamond E.N.™ coatings.

NIBORE™

There’s a lot to love about Bales’ proprietary NIBORE coating™. It offers superior lubricity and release, excellent abrasion resistance, plus uniform plating.

- 0.05 > Coefficient of Friction

- 54 Rockwell Hardness

- 0.00005 to 0.0005” Plating Thickness Range

Diamond E.N.™

Diamond E.N.™ provides exceptional abrasion resistance by combining Electroless Nickel and nano-sized diamond particles. With a low coefficient of friction, this proprietary coating can take on your wear and release issues all at once.

- 0.10 Coefficient of Friction

- 57 Rockwell Hardness

- 0.00005 to 0.0005” Plating Thickness Range

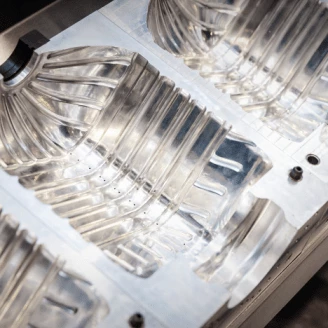

Case Study: NIBORE™ Expands Mold Potential & Life

With the adaptation and implementation of automation in manufacturing, machines and systems can run 24/7. Due to this extended run time, a customer was facing excessive downtime due to mold sets, broken blade and ejector pin replacement, and customer delay.

READ CASE STUDY