Hard Chrome Plating Is Tried And True,

For Good Reasons

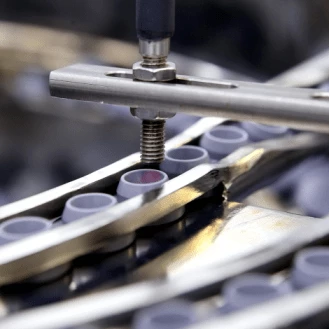

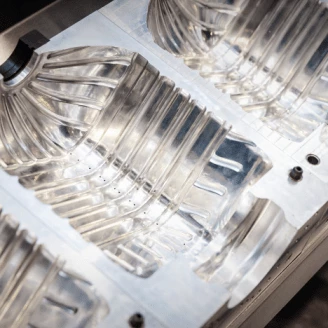

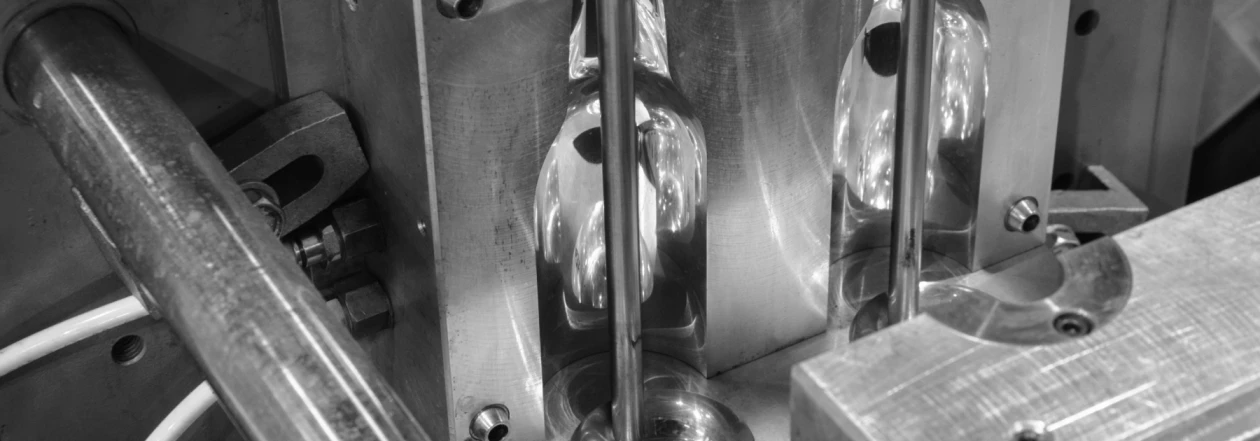

The widely used Hard Chrome plating process continues to be a go-to for industrial manufacturers. This is thanks to the superior abrasion and wear resistance of Hard Chrome plating. Hard Chrome plating solutions also offer moderate protection for metal components.

Here are some quick stats on Hard Chrome plating:

Additional Hard Chrome Plating Benefits

Abrasion and wear-resistant qualities are why customers keep coming back to Bales' Hard Chrome plating services. A few more reasons to choose Hard Chrome plating for industrial manufacturing include:

Why Hard Chrome is a Practical Solution

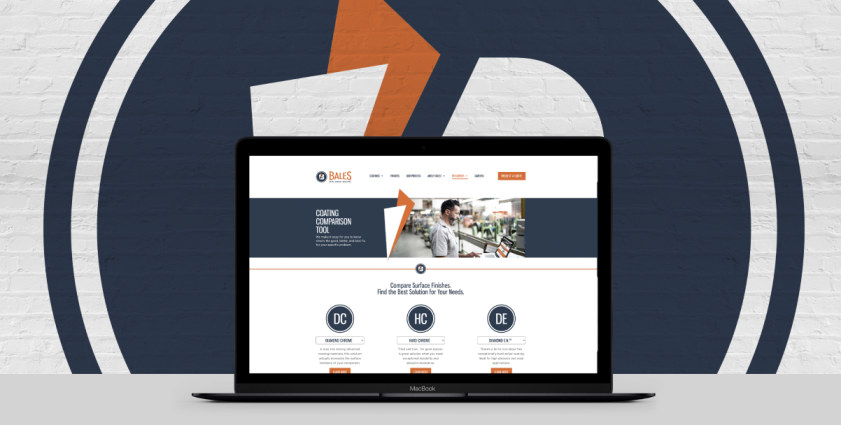

The attributes of Hard Chrome plating make it a reliable and durable coating for numerous industrial applications. Use our Coating Comparison Tool to see how Hard Chrome stacks up against other Bales coatings. Compare surface finishes and find the best solution for your needs.

BALES HAS YOUR SURFACE SOLUTION!

REQUEST A QUOTE TO GET STARTED.

FAQs ABOUT HARD CHROME PLATING

Discover the benefits of Hard Chrome plating in industrial settings and the steps Bales takes to address common challenges in the plating process. Plus, find out why Hard Chrome is a cost-effective solution for adding durability and reliability to metal components.