Precision Coatings for Maximum Component Functionality

Power Up Your Parts Performance with Bales

Analysts expect the share of renewable energy in the U.S. electricity generation mix to double by 2050, reaching over 40%.* With growing demand worldwide, many energy companies are just trying to keep up.

You can improve productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for energy companies worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From gears to rotors, your energy components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Energy Solutions FAQs

Energy sector components face extreme conditions, requiring robust coatings. This FAQ section discusses our solutions tailored to this demanding industry. Understand how our precision coatings enhance efficiency and durability in energy applications and discover our commitment to empowering the energy production industry with innovative solutions.

If you're ready to request a quote for your energy-related project, visit our dedicated Request a Quote page and get started today.

Our dedicated FAQ page offers more insights to help you make the right decision for your needs.

- Yes, both coatings maintain the precision and performance of critical components. Electroless Nickel, with its ultra-thin plating thickness, ensures that dimensional tolerances are met without altering the component's surface finish. Nickel Boron's uniform plating and excellent abrasion resistance ensure that high-precision components, such as valves and gears, operate smoothly and efficiently, even in demanding energy production applications.

- These advanced coatings not only protect against wear and corrosion but also contribute to the longevity and reliability of equipment used in energy production.

Solve Your Corrosion and Release Issues

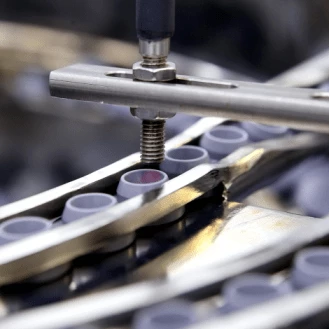

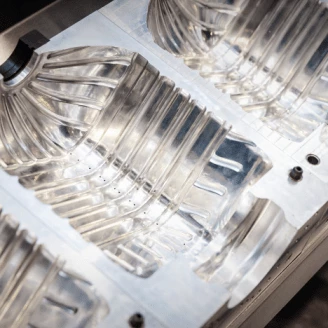

Bales’ Electroless Nickel and proprietary NIBORE™ coatings are ideal for preventing wear and sticking in energy components. In some applications, a combination of plating and polishing will achieve the most optimal results.

Electroless Nickel

Bales’ exceptionally thin Electroless Nickel coating protects against corrosion and abrasion without altering the surface finish of your mold. It also prevents build-up and maintains tolerance.

- .003” > Plating Thickness

- 1.0 mil deposit, 1,000+ hours Corrosion Properties

- 45 Rockwell Hardness - HVN100

NIBORE™

There’s a lot to love about Bales’ proprietary NIBORE™ coating. It offers superior lubricity and release, excellent abrasion resistance, plus uniform plating.

- 0.05 > Coefficient of Friction

- 54 Rockwell Hardness

- 0.00005 to 0.0005” Plating Thickness Range