There’s A Lot to Love About NIBORE™

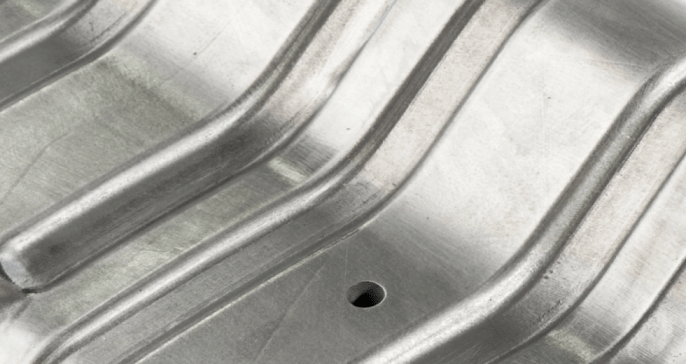

NIBORE™ is a proprietary nickel boron coating that offers a superior level of lubricity and release, an excellent level of abrasion and wear resistance, plus an extremely low coefficient of friction. Electroless plating doesn’t require an electric current; thus, NIBORE™ nickel boron coatings will be even, regardless of the surface.

Additional NIBORE™ Nickel Boron Coating Benefits

Explore the additional benefits of NIBORE™ nickel boron coating for any application.

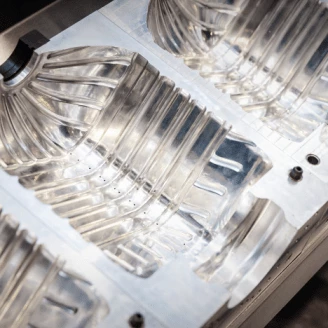

Why NIBORE™ Is Your Go-To Release Coating

Do you have a mold that requires exceptional release? The properties of our proprietary NIBORE™ coating make it an ideal option. Use our Coating Comparison Tool to see how NIBORE™ stacks up against other Bales coatings. Compare surface finishes and find the best solution for your needs.

““Bales’ customer service has been fantastic. They are extremely responsive to our needs, turning things around quickly..."”

Read Case Study

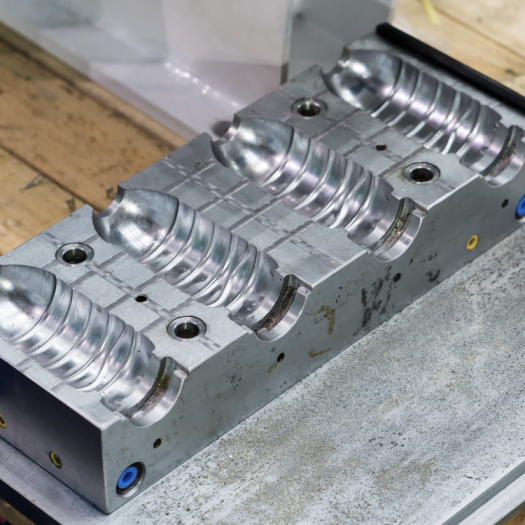

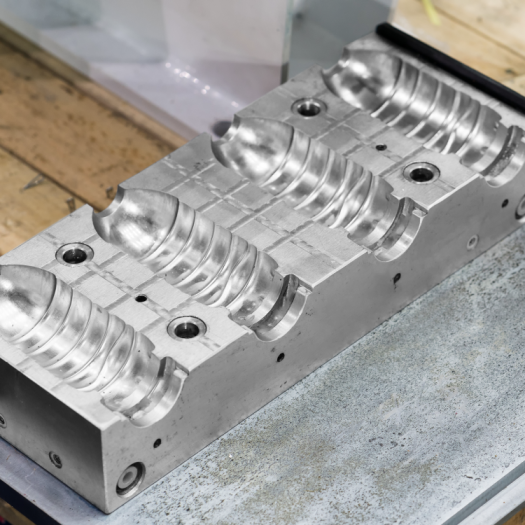

Case Study: NIBORE™ Solves Beryllium Copper Leaching Problem

A custom plastic injection mold manufacturer tested numerous coatings from different platers, but none stopped its beryllium copper mold from leaching into the product. The story was different once they approached Bales. “Bales’ customer service has been fantastic. They are extremely responsive to our needs, turning things around quickly, whether quotes or the plating process," said Rob Zimmerman, engineering manager at MOS Plastics.

READ CASE STUDY

BALES HAS YOUR SURFACE SOLUTION!

REQUEST A QUOTE TO GET STARTED.

FAQs about Nickel Boron Nitride Coating

Nickel Boron Nitride coatings offer exceptional hardness and wear resistance, plus excellent lubricity. They are ideal for applications requiring both durability and release, including consumer products, machined components, and automation & linear motion. Keep reading to discover how these coatings provide lasting metal surface protection.