Precision Coatings for Enhanced Aerospace Performance

Boost Your Parts Performance

with Bales

Aerospace manufacturers are bracing for an estimated 4.1% market growth from 2020 to 2027. But analysts say the competition is stiff when it comes to parts quality and design.*

You can step up your productivity and stand out by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for aerospace manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From weights to washers, your aerospace components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Aerospace Solutions FAQs

Precision is crucial in the aerospace sector. Bales Metal Surface Solutions provides specialized coatings and finishes that adhere to this industry's stringent standards. Our FAQ section offers answers about how our expertise in precision coatings can improve aerospace components' durability, performance, and reliability. Gain insights into selecting the right coating for your specific aerospace needs.

If you are prepared to take your aerospace project to the next level and need a precise quote, please visit our Request a Quote page and get started today.

Not quite ready yet? Find more information on our dedicated FAQ page.

- Corrosion Resistance: Electroless nickel plating provides a protective barrier that enhances the substrate's corrosion resistance, extending the lifespan of the coated component.

- Wear Resistance: The plated layer adds hardness and wear resistance to the substrate, making it more durable and suitable for applications with friction or abrasion.

- Uniform Coating: Electroless nickel plating ensures an even and consistent coating thickness, even on complex or irregularly shaped parts.

- Chemical Stability: The right plated surface is chemically stable and can withstand exposure to various chemicals and environmental conditions.

Solve Your Corrosion and Abrasion Issues

Aerospace manufacturers need to maximize productivity. Bales’ coatings enhance oxidation and wear resistance, extending the life of your aerospace components. Looking for the highest quality, uniform finish? Bales uses a light blast process to obtain a clean foundation before plating.

Electroless Nickel

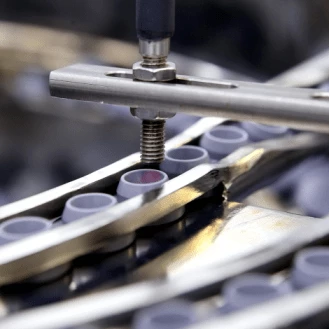

Bales’ exceptionally thin Electroless Nickel coating protects against corrosion and abrasion without altering the surface finish of your mold.

- .003” > Plating Thickness

- 1.0 mil deposit, 1,000+ hours Corrosion Properties

- 45 Rockwell Hardness - HVN100

BLASTING

Achieve a clean foundation for the highest quality finish on your mold, no matter its shape, size, or material. Bales provides high-quality mold blasting services that effectively remove surface imperfections from your mold.

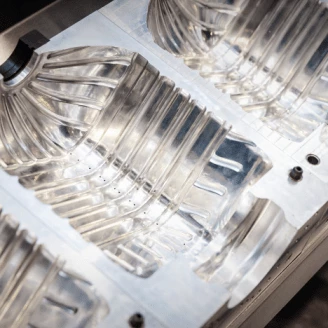

Case Study: Conforming Anodes Transform Coating

An aerospace manufacturer improved hard coating quality and efficiency with Bales. We used conforming anodes to plate its large-diameter molds with Hard Chrome in one shot, delivering as promised with a quick turnaround.

READ CASE STUDY