Achieve Your Ideal Surface Treatment

Enhance Your Parts Performance with Bales

After a sharp decline in 2020, the global medical device market is facing a resurgence. The number of inpatient admissions and medical procedures is rising, leading to an estimated 5.4% market growth rate from 2021 to 2028.* But supply chain disruptions are making it difficult for manufacturers to satisfy demand.

You can improve productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for medical device manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From face masks to respirators, your medical components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Medical Solutions FAQs

Quality and safety are paramount in the medical field. Our coatings for medical applications, detailed in this FAQ section, meet the highest standards. Discover how our durable, biocompatible, and regulation-compliant coatings enhance medical devices and equipment.

We welcome you to our Request a Quote page, where you can get a precise quote on your medical application coating needs today.

Need more details? Our dedicated FAQ page is a valuable resource for additional information.

Solve Your Metal Surfacing Issues

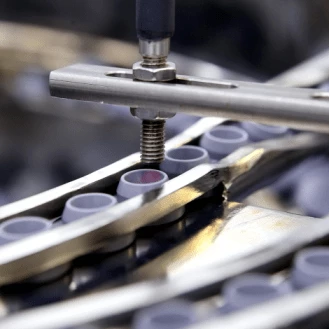

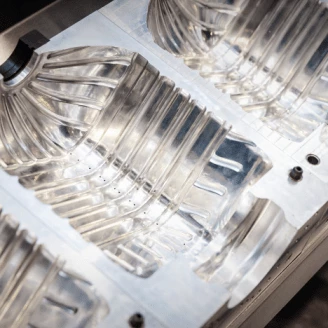

Medical device manufacturers need to maximize productivity. Boost yours with Bales’ Electroless Nickel, Hard Chrome, and proprietary NIBORE™ coatings, ideal for achieving corrosion resistance and optimal lubricity and release. Use Bales’ quality mold polishing service to obtain a specific finish and stainless steel passivation service for maximum oxidation protection.

NIBORE™

There’s a lot to love about Bales’ proprietary NIBORE coating™. It offers superior lubricity and release, excellent abrasion resistance, plus uniform plating.

- 0.05 > Coefficient of Friction

- 54 Rockwell Hardness

- 0.00005 to 0.0005” Plating Thickness Range

Electroless Nickel

Bales’ exceptionally thin Electroless Nickel coating protects against corrosion and abrasion without altering the surface finish of your mold. It also prevents build-up and maintains tolerance.

- .003” > Plating Thickness

- 1.0 mil deposit, 1,000+ hours Corrosion Properties

- 45 Rockwell Hardness - HVN100

NICKLON™

Bales’ proprietary NICKLON™ coating combines Electroless Nickel with PTFE. It protects against wear and corrosion while providing superior lubricity and release.

- 45 Rockwell Hardness

- 0.10 Coefficient of Friction

- PTFE 8-9% Composition (WT)

Case Study: NIBORE™ SOLVES LEACHING PROBLEM

Beryllium copper lends itself well as a material for plastic injection molds. For that reason, MOS Plastics used beryllium copper for the mold microplates it designed and built for a medical device customer. However, a problem arose as the customer started production.

READ CASE STUDY