THE CHALLENGE

Beryllium copper lends itself well as a material for plastic injection molds. Its heat transfer properties aid release, reducing cycle times and making the alloy especially effective for complex molds.

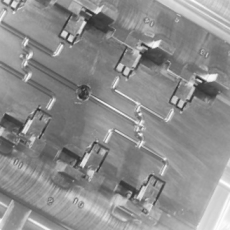

For that reason, MOS Plastics used beryllium copper for the mold microplates it designed and built for a medical device customer.

“They have a very complex geometry,” said Rob Zimmerman, engineering manager at MOS Plastics, a high-precision, custom plastic injection molded parts manufacturer. “The tooling comprises six tooling elements that fit like a jigsaw puzzle and form the features in the molded part.”

However, a problem arose as the customer started production. Traces of copper were leaching into the product, contaminating it and rendering it nonfunctional. Acting quickly to resolve the issue, MOS Plastics sought to coat the tool. “We needed a barrier between the base copper and parts we were molding,” Zimmerman says.

THE SOLUTION

Unfortunately, there was no easy solution. The company tested a variety of different coatings from different platers, but none kept the copper from migrating to the plastic. The story was different once MOS Plastics approached the Bales team.

After listening and asking many questions, a Bales technical service manager conducted some research and consulted Bales’ in-house chemist. Ultimately, he recommended lightly glass beading and masking the tooling to create buildup in an undersized area, then coating the tooling with NIBORE™, our exceptionally hard nickel coating.

THE RESULT

That process brought success. NIBORE™ provided the protection needed to stop the copper from leaching. MOS Plastics has relied on Bales ever since. They’re now using our process for continued success on this project.

Zimmerman appreciates the “above and beyond” attention. “Bales’ customer service has been fantastic,” he says. “They are extremely responsive to our needs, turning things around quickly, whether quotes or the plating process.”

"Bales’ customer service has been fantastic"

Rob ZimmermanEngineering Manager at MOS Plastics

“They are extremely responsive to our needs, turning things around quickly, whether quotes or the plating process.”

Rob ZimmermanEngineering Manager at MOS Plastics

No matter what challenge you face with your molds, Bales will deliver the right solution, on time, with the highest of standards. Learn more about NIBORE™.

CONTACT ON-CALL SUPPORT

CHAT LIVE

Chat live online with a Bales application expert Monday-Friday from 7 a.m. to 3 p.m. CT.

EMAIL US

Send Bales an email, and an application expert will reply within one business day.

BOOK APPOINTMENT

Book a phone call, video chat, or in-person appointment with a Bales application expert.