Achieve Your Ideal Surface Treatment

Accelerate Your Parts Performance with Bales

Analysts expect the global auto market to grow by 9% in 2021.* But COVID-19 is fueling supply chain disruptions and unplanned downtime, making it difficult for manufacturers to meet demand.

You can boost productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for automotive manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From headlights to engine covers, your automotive components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Automotive Solutions FAQs

Performance and reliability are critical in the automotive industry. Our coatings, detailed in our FAQs, meet these exacting standards. Learn how our precision solutions resist wear, combat corrosion, and extend the lifespan of automotive parts, reflecting our commitment to quality and innovation in the automotive sector.

If you are ready to enhance your automotive projects with our specialized coatings, please visit our Request a Quote page and get started today.

Need more insights before making a decision? Our dedicated FAQ page is here to help.

- Yes, chrome plating is known for its excellent corrosion resistance properties, which makes it effective in preventing rust. The chrome plating process involves adding a layer of chromium onto a metal substrate, typically steel or other metals. This chromium layer acts as a protective barrier that shields the underlying metal from exposure to moisture, oxygen, and other environmental factors that lead to rust or corrosion.

- Chrome plating is commonly used on various metal components, and industrial equipment, where preventing rust and maintaining a polished appearance are essential due to the protective layer chromium provides.

- Corrosion Resistance: As mentioned earlier, chrome plating provides exceptional corrosion resistance, making it suitable for components exposed to moisture, chemicals, and other corrosive elements.

- Easy Cleaning: The smooth and non-porous nature of chrome-plated surfaces makes them easy to clean and maintain, reducing the buildup of molding material.

- Chemical and Heat Resistance: Chrome plating offers resistance to certain chemicals and can withstand moderate levels of heat, making it suitable for components used in various environments.

- Electrical Conductivity: Chrome plating can enhance electrical conductivity, making it useful for applications that require good electrical performance.

- Reduced Friction: Chrome plating can reduce friction and improve the surface's lubricity, making it suitable for components with sliding or moving parts.

Solve Your Abrasion and Release Issues

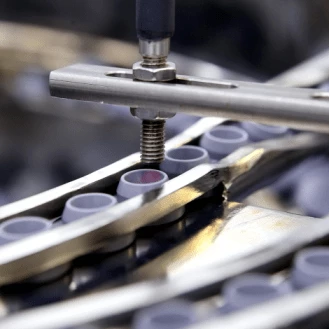

Automotive manufacturers need to maximize productivity. Boost yours with Bales’ Hard Chrome and proprietary NICKLON™ and Diamond E.N.™ coatings, Ideal for preventing wear and sticking in automotive components. Use our combined plating and polishing services to achieve your finishing specs.

Hard Chrome

Thanks to superior abrasion resistance, Hard Chrome is a reliable and durable coating for automotive applications. It’s also non-magnetic and mimics the finish of base materials.

- 72 Rockwell Hardness

- 1250°F Max Operating Temperature

- 6.9 g/cm3 Density

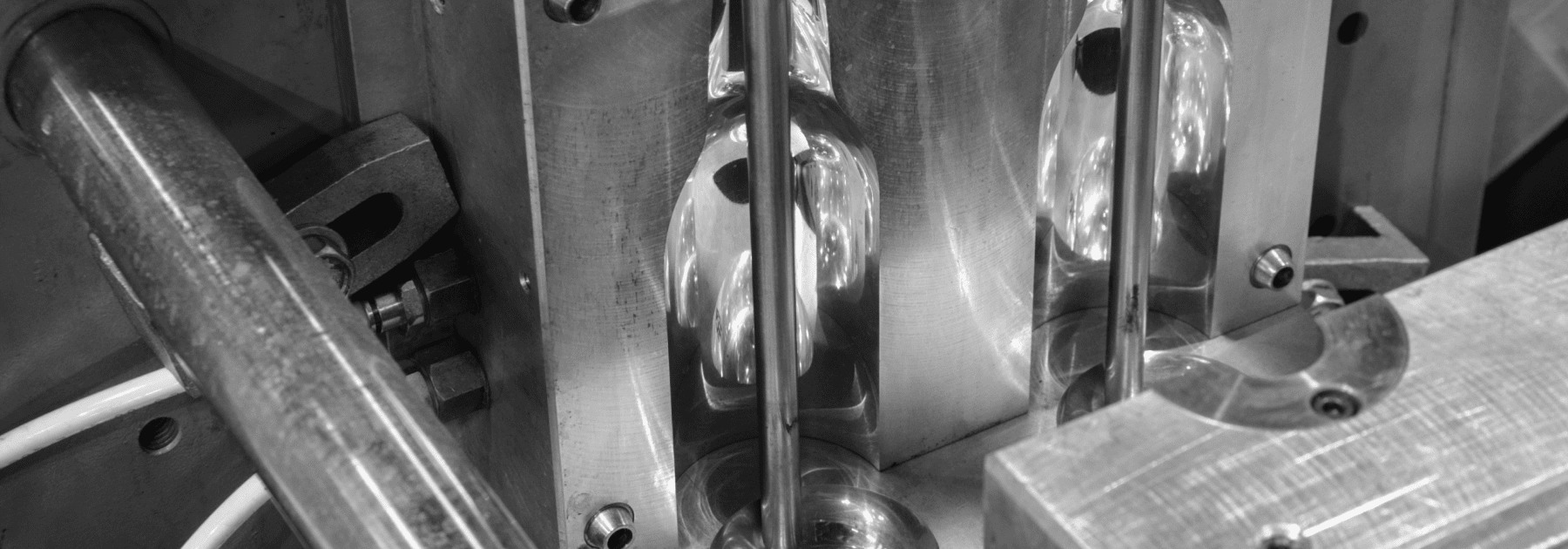

NICKLON™

Bales’ proprietary NICKLON™ coating combines Electroless Nickel and PTFE, making it a go-to solution for automotive applications. Protect against wear and corrosion while achieving optimal lubricity and release.

- 45 Rockwell Hardness

- 0.10 Coefficient of Friction

- PTFE 8-9% Composition (WT)

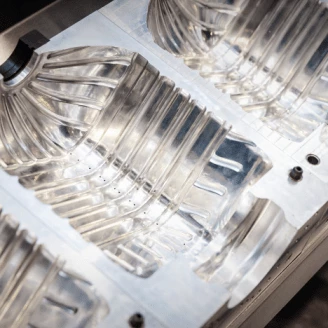

Diamond E.N.™

Electroless Nickel combines with nano-sized diamond particles to form Bales’ proprietary Diamond E.N.™ coating. With a low coefficient of friction, Diamond E.N.™ can take on your wear and release issues all at once. It’s also a faster, more cost-efficient alternative to Hard Chrome.

- 0.10 Coefficient of Friction

- 57 Rockwell Hardness

- 0.00005 to 0.0005” Plating Thickness Range