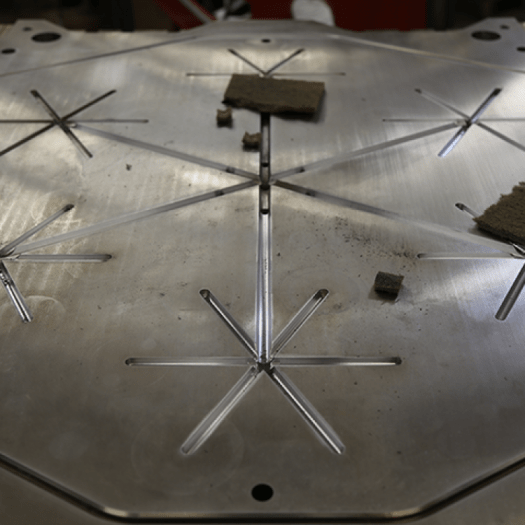

Diamond Chrome Coating For

Your Most Abrasive Applications

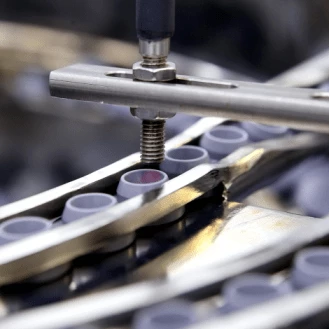

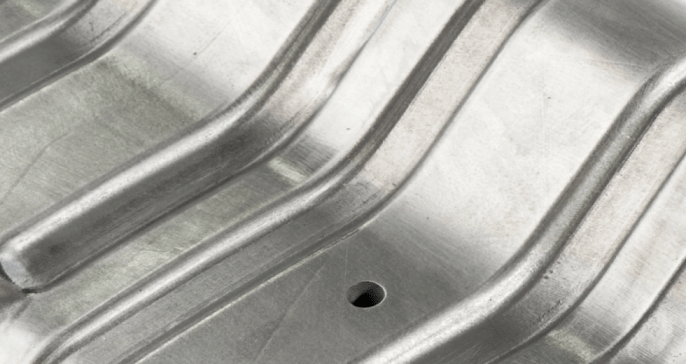

Nanometer-sized diamond particles are co-deposited with chrome plating for long-lasting abrasion protection with excellent lubricity and release. This is why Bales recommends Diamond Chrome coating for all of your most abrasive applications.

Additional Diamond Chrome Coating Benefits

What else can a Diamond Chrome coating bring to your molds and components?

Why Diamond Chrome Rules Resistance Coatings

Diamond Chrome contains nano-sized diamond particles that make it the most wear-resistant coating and the best solution for abrasive applications. Use our Coating Comparison Tool to see how Diamond Chrome coating stacks up against other Bales coatings. Compare surface finishes and find the best solution for your needs.

BALES HAS YOUR SURFACE SOLUTION!

REQUEST A QUOTE TO GET STARTED.

“From start to finish, it was a pleasure working with Bales.”

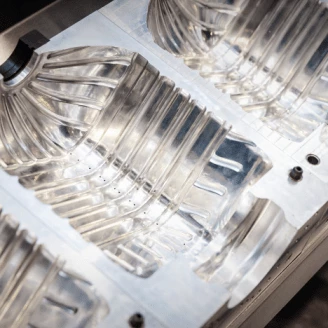

Read the full case study to learn how Diamond Chrome coating solved Plastic Ingenuity's issue with sticking and wear on injection molding tools.

Read Case Study

Case Study: The right coating and process is key to boosting productivity

One of the largest custom thermoformers in North America prides itself on being solutions-oriented when working with customers and appreciates how Bales took the same approach in solving their complex challenges. “We take the time to develop the right solutions for our customers, and we expect our vendors to do the same for us," said Pete Laubmeier, sales engineer at Plastic Ingenuity, Inc.

READ CASE STUDY

FAQS ABOUT DIAMOND CHROME PLATING

Discover why Diamond Chrome plating is the superior choice for the most abrasive applications. Read our FAQs to learn about its durability and cost-effectiveness compared with standard chrome, plus its advantages for specific industries.