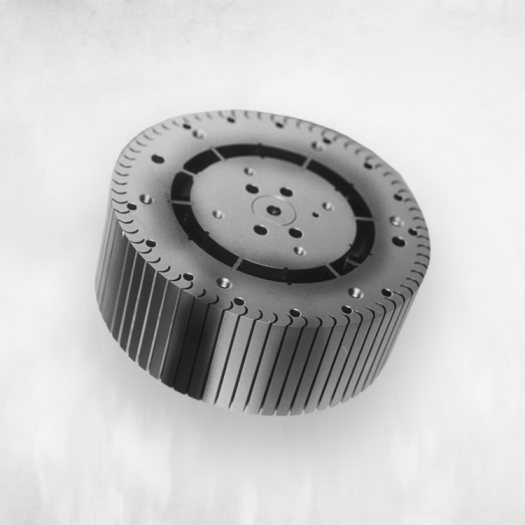

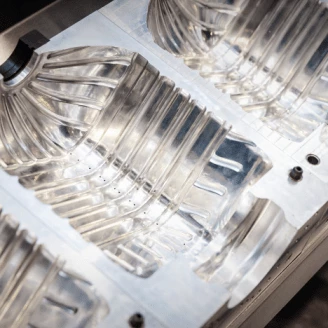

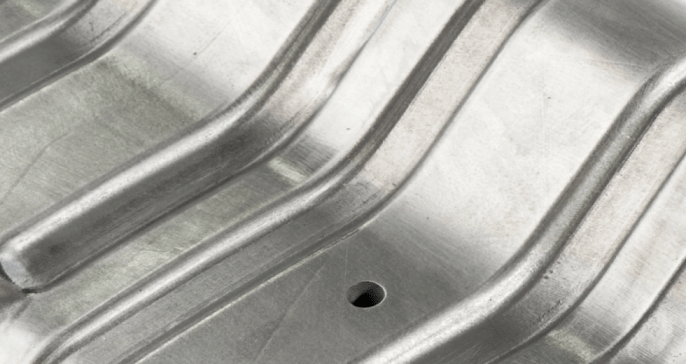

Electroless Nickel Plating Is The Choice For Coating Corrosion Prone Materials

Electroless Nickel plating creates a thin, uniform coating that offers superior protection against oxidation, along with moderate abrasion resistance properties.

Why Electroless Nickel Maximizes Corrosion Protection

The properties of Electroless Nickel plating provide superior corrosion resistance without altering the surface finish of your mold. Use our Coating Comparison Tool to see how Electroless Nickel plating stacks up against other Bales coatings. Compare surface finishes and find the best solution for your needs.

A Real Electroless Nickel Success Story

See Electroless Nickel plating in action with a real Bales customer.

““Reducing cycle time by 32% was huge —

an immediate ROI.” ”

Read our full case study for Phoenix Proto Technologies, a real Bales customer who saw an incredible reduction in cycle time with Electroless Nickel plating.

Read Case Study

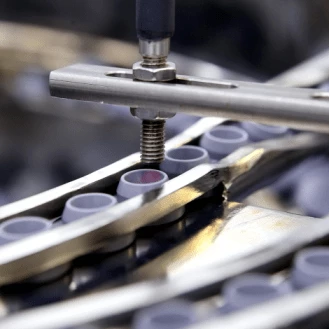

Case Study: Electroless Nickel Effectively Coats Buoyant Part

A metal float ball manufacturer needed help after its long-time plating supplier went out of business. But plating buoyant parts is challenging. Bales stepped up to the task, developing a custom coating solution that reduced processing time and costs. “Bales was the only one who could come through for us. Others just couldn’t meet our needs.” - Jason Speer, President of Quality Float

READ CASE STUDY

BALES HAS YOUR SURFACE SOLUTION!

REQUEST A QUOTE TO GET STARTED.

FAQS ABOUT ELECTROLESS NICKEL PLATING

Check out our FAQs to explore how Electroless Nickel compares to standard nickel plating. You’ll learn what makes it ideal for metal components, its benefits for various industries, and how it’s able to resist corrosion so effectively.